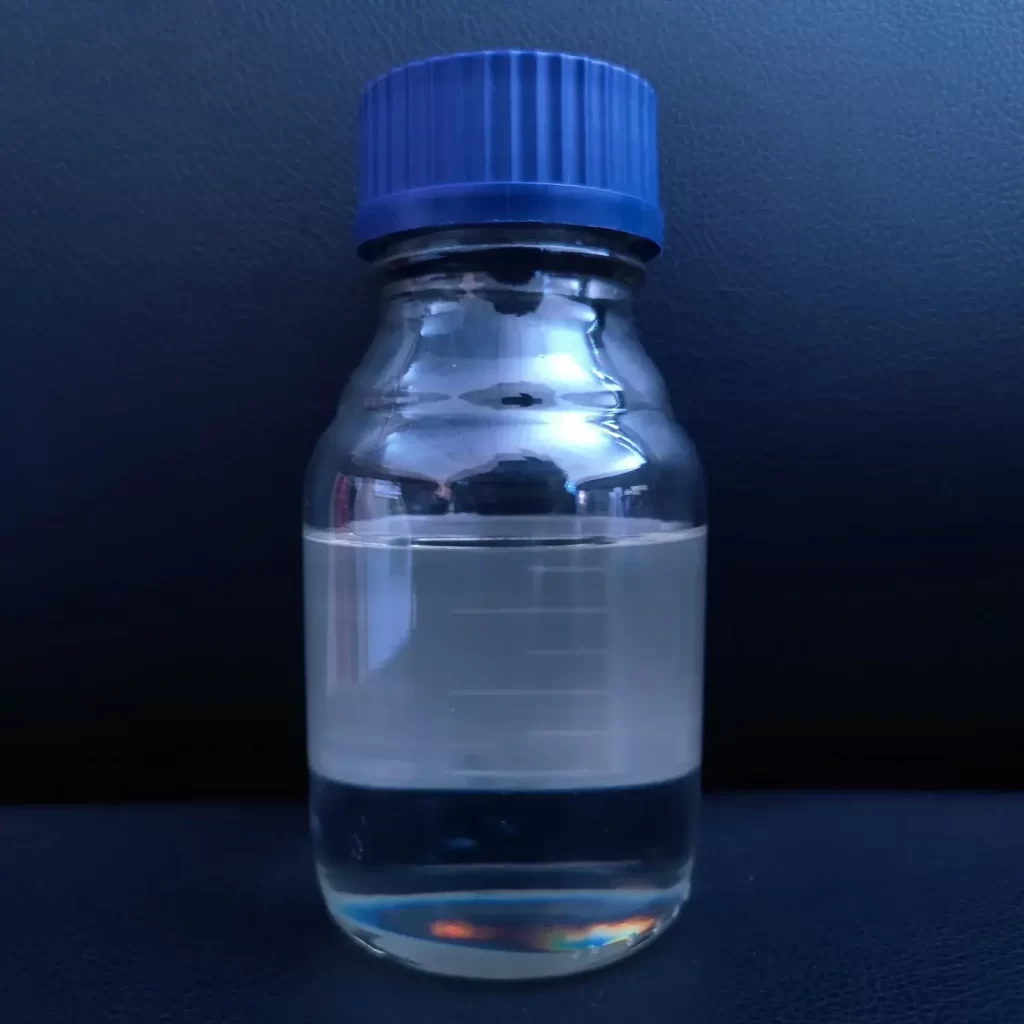

Epoxy Resin

Additionally, epoxy resins play a key role in aerospace and automotive industries for lightweight yet strong composite parts. Their ability to be customized with modifiers and curing agents allows them to meet specific performance requirements for various applications, such as coatings, tooling, marine uses, electronics, and art.

Act of putting on

Paints and coatings

Epoxy resin coatings are extensively used as anti-corrosion paints for metals. They provide strong adhesion to metal surfaces and protect them from rust, chemicals, and environmental degradation, making them ideal primers for steel structures and machinery.

Construction

Epoxy resin is commonly used to repair and bond concrete by filling cracks and gaps in concrete structures. It provides a strong, durable bond that restores structural integrity in bridges, buildings, and infrastructure.

Turbine technology

Epoxy resins are the key materials for producing wind turbine rotor blades. They are combined with reinforcing fibers such as glass or carbon fiber to form composites that are both lightweight and strong. These composites allow for larger blade sizes.

Electronics

Epoxy resins are used to encase sensitive parts like integrated circuits, transistors, and modules. This protects the components from moisture, dust, mechanical damage, and environmental factors while enhancing electrical insulation.

Aerospace

Epoxy resins are used as the matrix material in carbon fiber and other fiber-reinforced composites that form primary and secondary structures of modern aircraft. This includes wings, fuselage sections, tail fins, and other components.

Biology

Epoxidized soybean oil (ESBO) is used in the rubber industry as a plasticizer to improve flexibility and processability. It enhances the dispersion of fillers like silica, improving mechanical properties and durability. ESBO also serves as an eco-friendly alternative to petroleum-based oils in rubber compounds.

Features

High Mechanical Strength

Epoxy resins offer remarkable tensile, compressive, and flexural strength that make them suitable for structural uses, load-bearing, and repairs under demanding conditions.

Strong Adhesive Properties

They bond securely to a wide variety of materials such as wood, metal, glass, concrete, and composites, ensuring long-lasting adhesion for coatings, laminates, and glues.

Chemical and Moisture Resistance

Epoxy resins are highly resistant to chemicals, solvents, and water, enabling them to perform well in harsh industrial and marine environments and in protective applications.

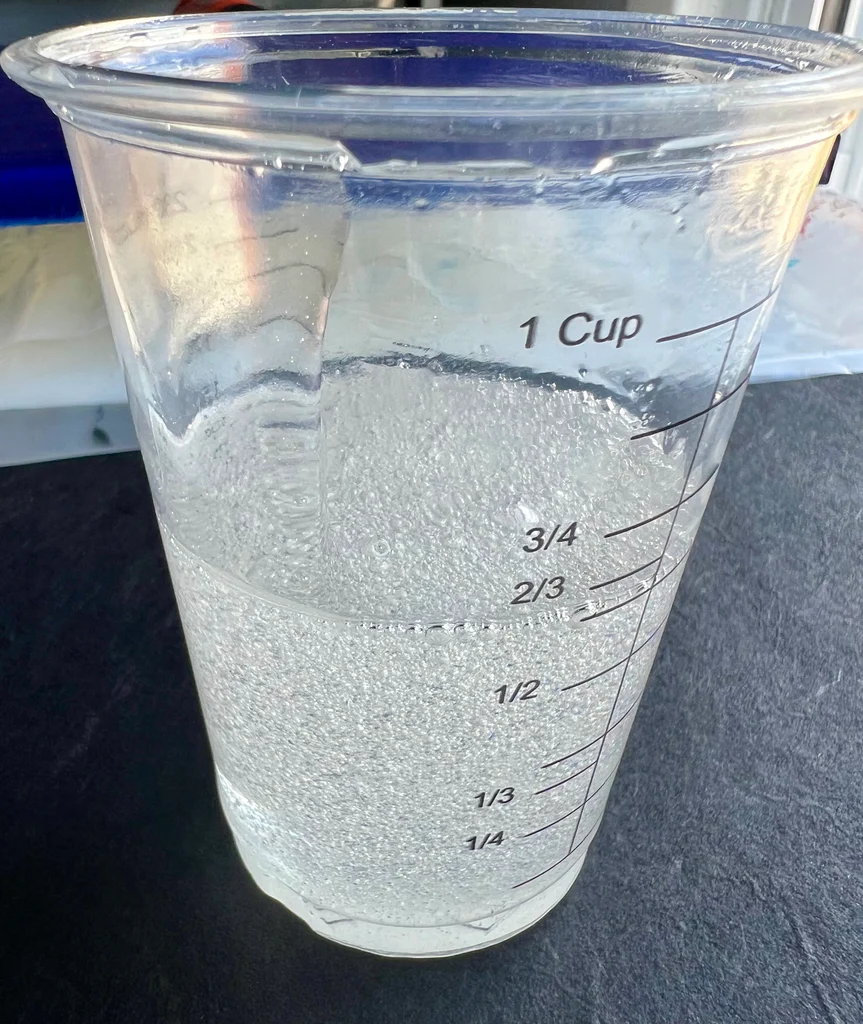

Low Shrinkage During Curing

They shrink very little upon curing, guaranteeing dimensional stability and preventing cracks—usually around 1% compared to 6% in polyester resins.