Epoxidised Soyabean Oil

ESBO is manufactured from soybean oil through the process of epoxidation. Polyunsaturated vegetable oils are widely used as precursors to epoxidized oil products because they have high numbers of carbon-carbon double bonds available for epoxidation. The epoxide group is more reactive than double bond, thus providing a more energetically favorable site for reaction and making the oil a good hydrochloric acid scavenger and plasticizer. Usually a peroxide or a peracid is used to add an atom of oxygen and convert the -C=C- bond to an epoxide group.

Act of putting on

PVC Pipes

This is added to PVC to make it softer, more flexible, and pliable. It embeds itself between the polymer chains, reducing their intermolecular forces, which allows the PVC to bend and twist without cracking

Soya based inks

This imparts flexibility and improves the film-forming properties of soy-based inks. This helps inks to dry evenly, form smooth films, and avoid cracking or brittleness on printed surfaces.

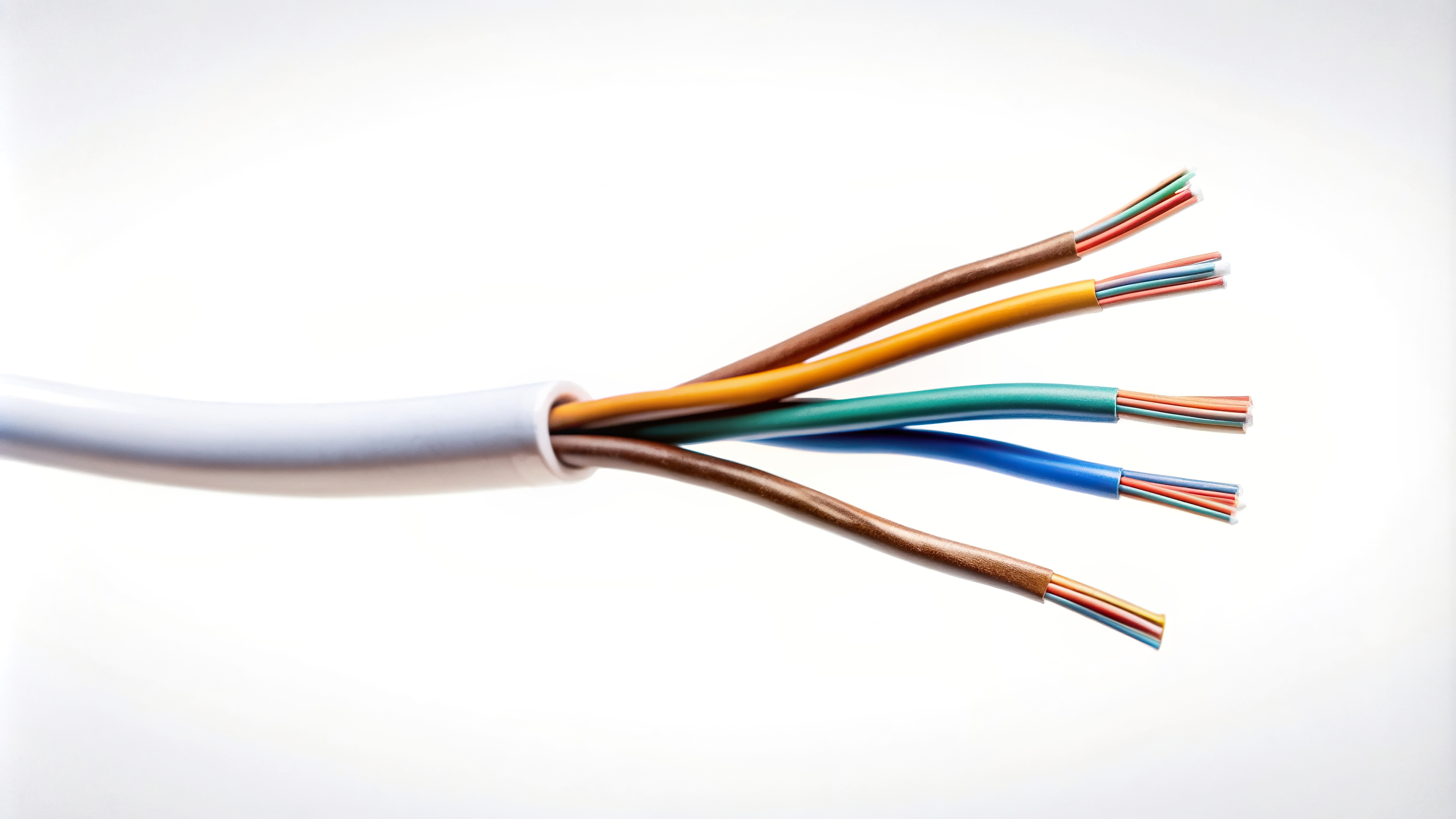

Wire & Cables

This is added to PVC to make it softer, more flexible, and pliable. It embeds itself between the polymer chains, reducing their intermolecular forces, which allows the PVC to bend and twist without cracking

Food Contact Applications

Due to its outstanding its compatibility with PVC and ability to neutralize acids, ESBO is a preferred, non-toxic, biodegradable, and phthalate-free additive for improving both the safety and performance of food packaging materials

In Agriculture

It is used in agriculture primarily as an inert ingredient in agricultural pesticides where it provides equipment corrosion protection. It also acts as an acid scavenger in soy-based agricultural chemicals and insecticides, improving their stability and performance.

Rubber Industry

This is used in the rubber industry as a plasticizer to improve flexibility and processability. It enhances the dispersion of fillers like silica, improving mechanical properties and durability. ESBO also serves as an eco-friendly alternative to petroleum-based oils in rubber compounds.

Features

Uses

Food products that are stored in glass jars are usually sealed with gaskets made from PVC. ESBO is one of the additives in the PVC gasket. It serves as a plasticizer and a scavenger for hydrochloric acid released when the PVC degrades thermally, e.g. when the gasket is applied to the lid and food product undergoes sterilization. ESBO is also used in PVC cling films for wrapping foods and toys.

Legislation

In Europe, plastics in food contact are regulated by Regulation (EU) 10/2011. It establishes a specific migration limit (SML) for ESBO of 60 mg/kg. However, in the case of PVC gaskets used to seal glass jars containing infant formulae and follow-on formulae as defined by Directive 2006/141/EC or processed cereal-based foods and baby foods for infants and young children as defined by Directive 2006/125/EC, the SML is lowered to 30 mg/kg. This is because babies have higher food consumption per body weight.

Toxicity

The tolerable daily intake (TDI) of ESBO defined by the Scientific Committee on Food (SCF) of the EU is 1 mg/kg body weight. This value is based on a toxicological assessment performed by the British Industrial Biological Research Association (BIBRA) in the late 1997. Repeated oral administration had been shown to affect the liver, kidney, testis and uterus of rats. According to the conventional European rules for food packaging materials, the TDI became a basis for the SML of 60 mg/kg

Food

A Swiss survey in June 2005 showed that (among many other plasticizers exceeding the legal limits) migration of ESBO into foods reached up to 1,170 mg/kg. Rapid Alert System in Food and Feed (RASFF) had also reported cases of food product rejection in EU for exceeding SML under EU Legislation (EC/2002/72). Enforcement authorities took measures to force producers respecting the legal limits.

Specifications

| GRADES | 20017 G | 20019 S | E 7200 |

|---|---|---|---|

| Appearence | Pale Yellow liquid | Pale Yellow liquid | Pale Yellow liquid |

| Iodine Value | 6.0 Max | 2.0 Max | 2.0 Max |

| Oxirane Oxygen % | 6.3+/-0.2 | 6.5+/-0.2 | 6.6+/-0.2 |

| Acid Value % | < 1 | < 1 | < 1 |

| Sp. Gravity At 30 degree C | 0.983 - 0.987 | 0.983 - 0.987 | 0.983 - 0.989 |

| Moisture Content % | 0.5% Max | 0.5% Max | 0.5% Max |

| Volatile Loss @130degree C,for 3 Hrs. | 0.30 Max | 0.30 Max | 0.30 Max |